Fuel/Fleet Management Systems

The high cost of business operations has made Fuel Management necessary, even compulsory for firms, establishments and organizations. Faced with the need to cut off losses and retain more profits, the high costs of fuel and fueling activities has been sought to be reduced. Many organizations, have tried certain processes, systems and initiatives to manage fuel usage and expenses; most of these have actually being wrongly applied and/or conceived leading to the problem remaining, and operational costs soaring.

Smartflow has since 2009 being at the forefront of providing well-crafted and customized Fuel Management Solutions for our clients. Put together, several billions of naira have been saved using Smartflow Fuel Management Solutions.

At Smartflow we define Fuel Management as the administration and control of the platforms, processes and systems that allow and guarantee the ability to accurately account for fuel products, either individually or collectively, at their points of receipt, storage, distribution and issuance.

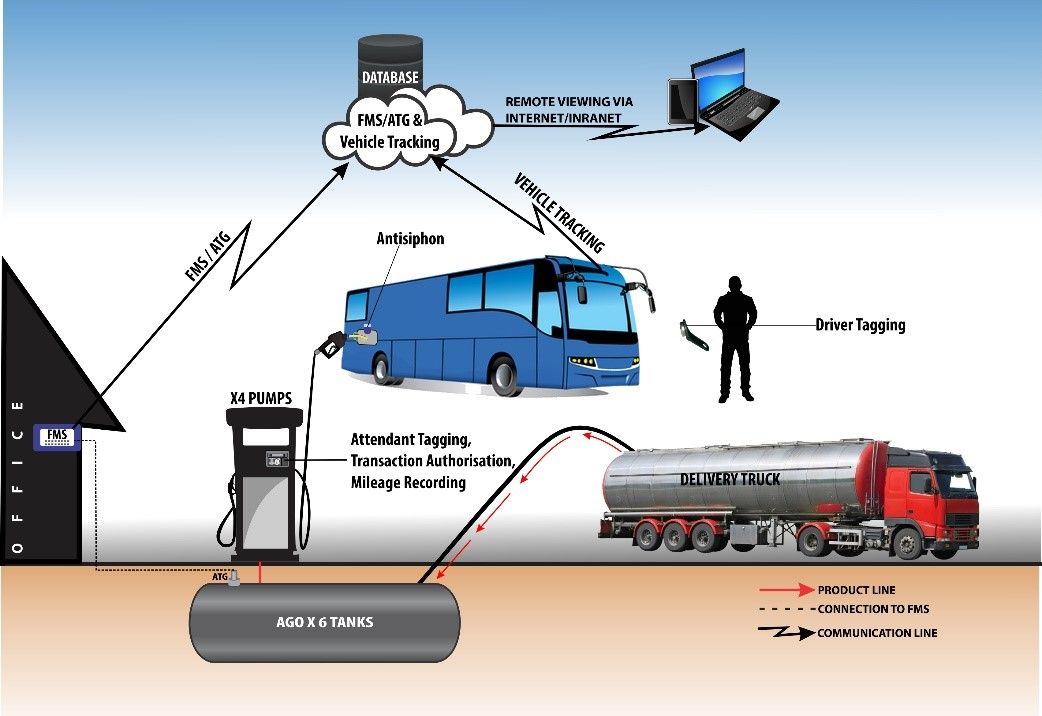

Owners of large fleet with commercial fueling setups, can manage their fleet, and block fueling leakages using Smartflow’s solution.

Through Smartflow solution, each vehicle/equipment is duly tracked and authorized to fuel within set limits. This brings accountability, control and advanced fleet data management.

Why not talk to us today to deploy a customized Fuel Management Solution for you.

Smartflow’s Fuel Management Solution always starts off from the ability to measure; this is based on our belief that, “You cannot Manage what you cannot Measure”.

Fuel Management Consoles

The fuel management console is designated to car fleet managers wishing to supervise and to secure fuel supply.

Features

- Real time communication between terminals and servers, via internet or intranet.

- Quick and efficient thanks to search engine and reports generator that enable a flexible and real customization of the product.

- Longevity of the equipment thanks to the use of resistant materials.

- Scalability based on functional modules able to control the following devices: fuel dispensing, oil dispensing, gate opening, carwash, electrical vehicles charging…

- Real-time or stand-alone operating

- Multi-site

- Connection TCP/IP network – Modem – RS232/485 – Wireless

- Simultaneous management of 1 to 16 pumps for each terminal

- Identification of drivers and/or vehicles by code or by different kinds of badges (proximity cards/keyfobs, magnetic cards, etc.)

- Manages a maximum of 15000 drivers and 15000 vehicles

- Stores up to 2500 transactions

- Remote control and supervision

- Alarm trigger with e-mail, fax or SMS notification

- Oil co. data input is performed easily. (Total, Shell, Esso, As24)

- Data output towards any application

- Real time transactions printing or tickets edition (optional)

- Automatic vehicles identity recognition (optional)

- Automatic mileage input can be performed directly from vehicles (optional)

- Digital tachograph driver card reader (optional)

- Simple web interface, accessible from any computer on the network.

- Management of fuel stocks, with levels’ chart

- Management of different kinds of users (passengers, subcontractors, customers, etc.)

- Management of maintenance actions with automatic recall

- Management of anomalies with recording of maintenance history, stocks states, variations in fuel consumptions, electrical shut down, etc.

Automatic Tank Gauge Systems

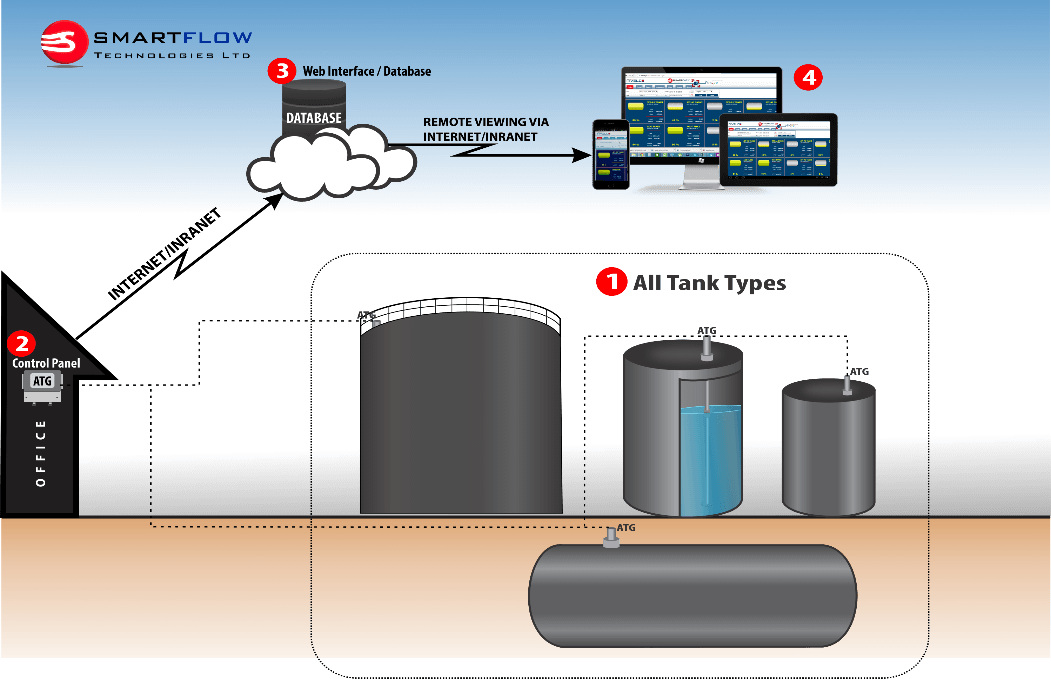

Automatic Tank Gauging systems (ATG) are primarily used to determine the level of fluids (and possibly granular solids) contained within a tank. The ATG through the determined levels processes and delivers additional information such as volume, ullage, water level, high alarms, low alarms, reorder alarms, overfill alarms and so on. Our ATG systems are designed to make data accessible either onsite or remotely via the internet.

How It Works

The probes are installed in the tanks, reading the level of fluid in the tank and continuously computing the volume. This information is sent to the control panel.

The control panel displays the levels and volumes in the tank locally/on site. This information is accessible through a clear user-friendly interface.

Data is stored on a dedicated remote server. No IT infrastructure is required by the customer.

The End user can also access the information by logging into the site. The End user can also get alert via emails or SMS on the levels/volumes of fluid in the tank per time.

The most frequent level instrumentation task is level control and limit level switching whether if the measurement medium is liquid or solid. This is the reason why SMARTFLOW focuses on level switches in addition to the level transmitters.

SMARTFLOW supplies the instruments that offer reliable level control and limit level switching solutions for most media from potable water to sewage, aggressive alkalis and acids, or free- flowing, powdered, bulk or granular solids. Thanks to this very wide level switch selection we are able to provide suitable instruments for most level instrumentation applications.

Most of our level switches have explosion-proof versions (in accordance to ATEX and/or IEC Ex). Moreover we offer suitable solutions for special requirements, for example the ship-building industry with a need for Germanischer Lloyd (GL), Det Norske Veritas (DNV), Bureau Veritas (BV) or SIL approvals.

- Compact, efficiently designed. 7” full-colour-touch-screen display

- Simple for authorized users to understand and operate while eliminating unauthorized access.

- Easily manage multiple tanks. Supports up to 64 inputs (probes)

- Web-Enabled: monitor and control your automatic tank gauge system from any web browser.

- Able to store measurement values and three additional parameters of the connected transmitters in a measurement system into the internal FLASH memory or an SD memory card

System Highlights:

- Battery backed systems available

- No IT infrastructure required

- Can connect to Local LAN or GPRS network

- Flexible probes available for tall tanks

- 1000+ working probes around Nigeria

- DC versions available

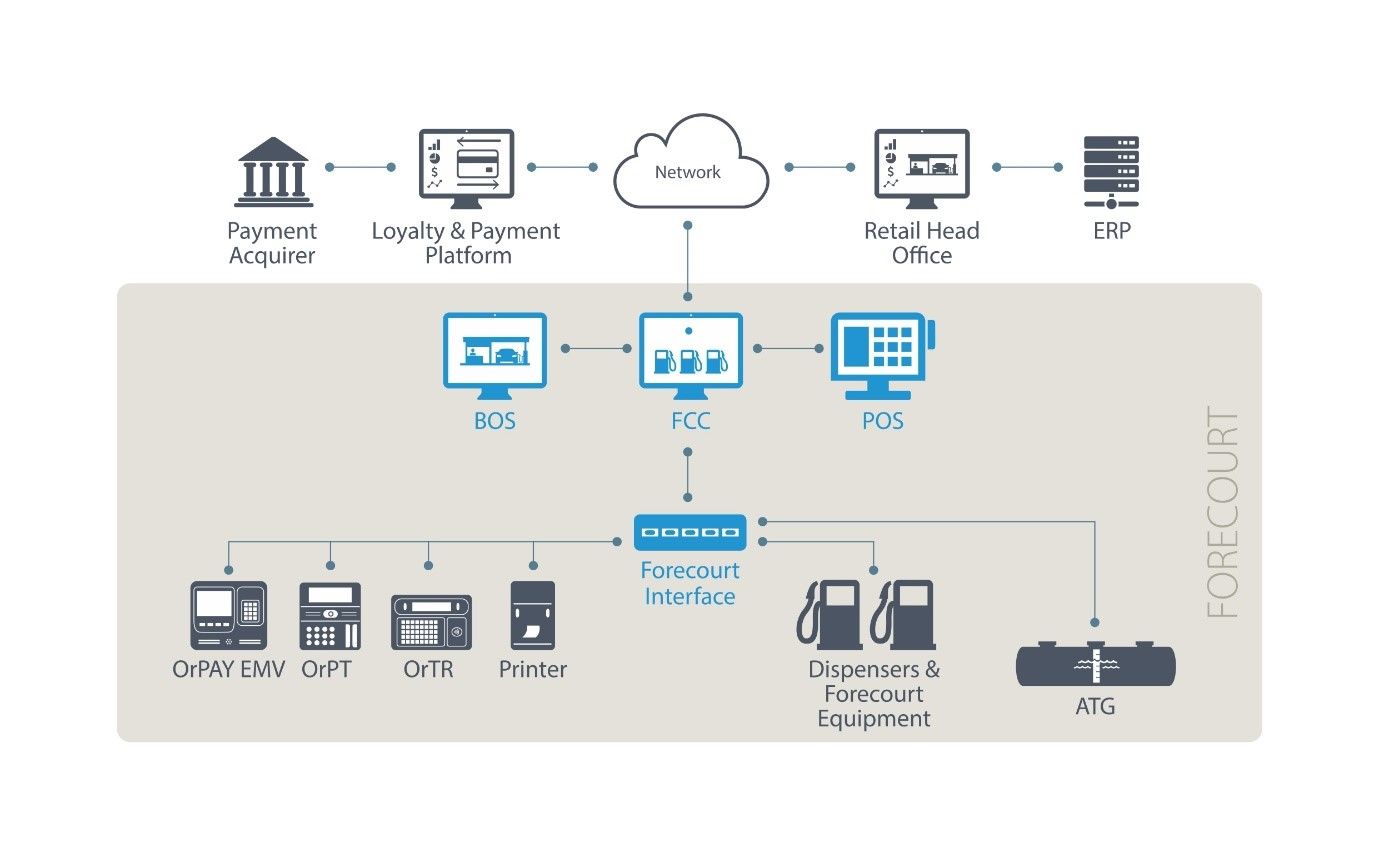

Forecourt Automation

Smartflow offers various solutions for effective and efficient Retail Station Management.

These solutions and capabilities deployed depend on actual needs of the station or station network. Smartflow’s Retail Station Management has an assortment of automation and non-automation components, all fully customized to the clients’ need.

Starting from providing high efficient pumps/dispensers, delivering calibration services in underground tanks, deploying Automatic Tank Gauges to Measure, and getting Forecourt Controllers to talk to the pumps, Smartflow’s solution ensure that your station runs profitably with leakage points blocked off.

Smartflow offers various solutions for effective and efficient Retail Station Management.

Smartflow’s Forecourt Automation Solution makes available powerful tools that help centrally manage and control your petrol station network either onsite or offsite. With the critical set of information and data available to prevent run-outs and dumping, while improving logistics efficiency.

Forecourt Interface Unit

The FuelNet Manager gives you real-time control and monitoring of your station or station network. Just log into the cloud-based interface and you have access to all of the controller’s functionality: Monitoring and controlling dispensers, price signs and ATGs etc. – plus managing wetstock, orders and distribution. The FuelNet Manager is designed for modern, lean fuel retail organizations and does not require staff on site to report and monitor the performance and functionality of forecourt equipment, check wetstock inventory or update pricing.

- Cloud-based access to the full controller functionality

- Monitor and control dispensers

- Monitor and control price signs

- Monitor and control automatic tank gauging (ATG)

- Wetstock inventory & reconciliation per site or network

- Delivery and volume history

Less Site Downtime

Get immediate notification in case of any malfunctions on site. Have them fixed quickly thanks to remote troubleshooting and remote diagnostics.

Easy to Install

Installing the FuelNet Manager is easy. The hardware is installed locally. Configuration and setup is managed remotely by trained support engineers.

Compatibility & Integration

The FuelNet Manager is designed for maximum compatibility and easy integration, using both standard and proprietary protocols to communication with new and old equipment alike. It integrates both with cloud-based and traditional POS systems.

Terminal Automation System

Smartflow’s Terminal Automation System manages product movements and inventory for any size terminal handling products by volume or mass, including:

- Asphalt

- Chemicals

- Crude/LNG

- LPG

- Refined Products

Smartflow’s Terminal Automation System also manages and automates both business and operations throughout the terminal:

- Securely manages terminal access by personnel and vehicles by verifying the validity of license, permits, and certificates

- Manages bulk product receipts and disposals (marine, pipeline, rail)

- Manages intra-tank farm activities (tank-to-tank transfers, in-tank reconsignments)

- Manages road loading and unloading orders

- Provides multi-level inventory accounting (tank physical, tank book, supplier, supplier/tank, gain/loss)

Our project team is:

Our project team is:

- Experienced in the oil, gas, and bulk liquid distribution sectors

- Guided by field-proven, documented project methodologies that are hailed by rigorous customer audits as unmatched in the industry

- Accomplished at delivering projects on time and on budget

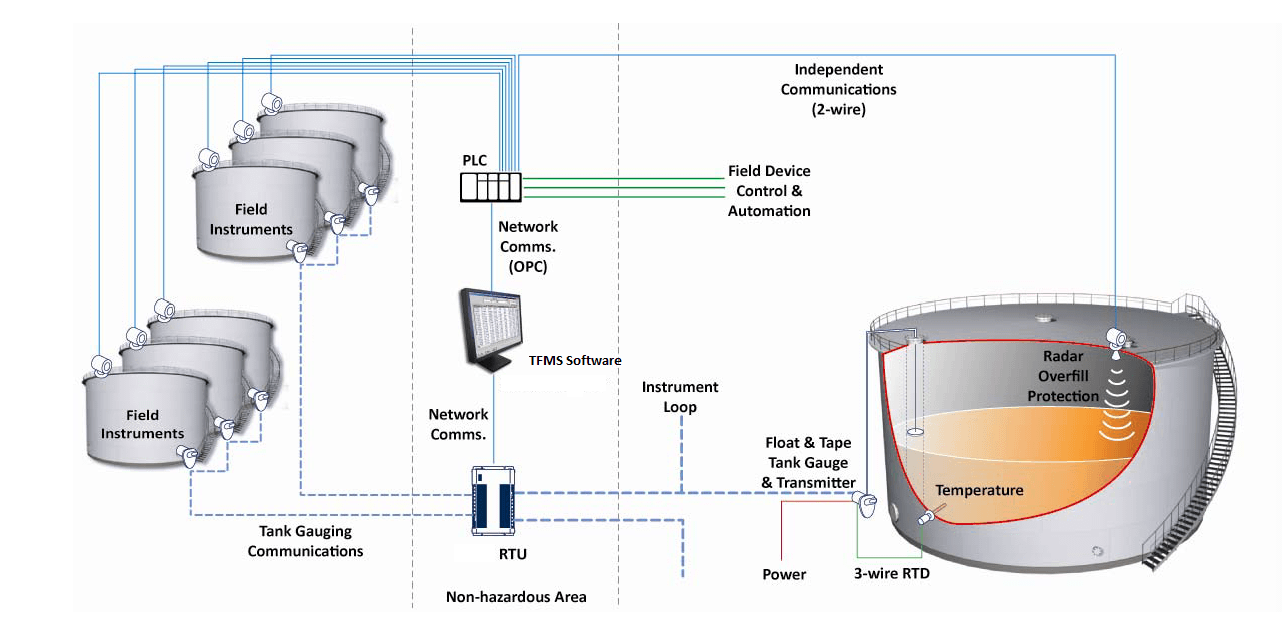

Tank Farm Management Systems

Using a combination of our Automatic Tank Gauges, Flow Measurement Solutions and Fuel/Fluid Management System, Smartflow is able to deliver Tank Automation solutions.

Our tank farm automation solutions continually leverages on the capabilities of the present technology while keeping an eye on new technologies.

Using our Tank Farm Automation solutions allows operators to plan product demand and supply, administer inventory, schedule orders. All this when rightly utilized lead to accurate issues and precise deliveries.

Level Monitoring And Automation

Smartflow is highly knowledgeable and experienced in providing superior and effective Level Monitoring & Automation solutions that ensure that facilities and operational premises deliver according to their metrics.

Our level solutions can be adapted for tanks, open channels, reservoirs, grain silos, pump control, liquid flow and the likes, utilizing ultrasound, microwave and magnetostrictive platforms to deliver accurate readings, information and analyses.

Another major highlight of Smartflow’s level solutions is the ability to provide remote information on the deployed level monitoring solutions.

Through Smartflow’s level monitoring and automation solutions, our clients enjoy;

- Improved visibility and control

- Ability to program activities and action at several fluid/dry levels

- Improved ability to track and record volumes and contents

- Reduced handling costs, thus improved bottom lines

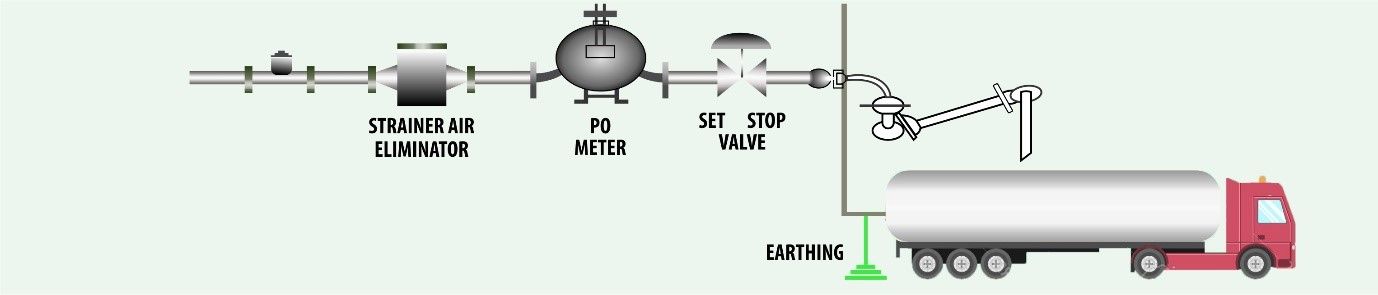

Flow Measurement And Automation

The importance of measuring anything that flows cannot be overstated. This even becomes more important when it comes to areas of Custody Transfers!

Smartflow Technologies applies experiences, knowledge, engineering competencies and where necessary, automation, to create the best flow measurement solution for our clients. As an add-on on this, we create processes and documentation to create fit-for-situation flow management guidelines.

Smartflow delivers the required solution in either as a consultant or as the implementer; all in all, our clients will definitely see marked improvement in their flow measurement regimes.

Smartflow has bouquets of solutions that automate the flow processes for facilities that deal with flowing fluids. The solution has the ability to improve operational performance and deliver high ease of control.

Our solutions direct, control and measure flows, instantly or over a period of time, while taking cognizance of the environment and safety.

E-Fueling

Smartflow is presently working assiduously with our key partners to deliver e-fueling solutions at Fuel Retail Stations. The solution being developed takes off from Smartflow deployment of Forecourt Controllers and Automatic Tank Gauges in filling stations.

The solution when fully deployed, will take into consideration several form of e-payments through various cards and sensors that will authorize fueling.

Are you interested in taking part in any beta testing, or informed when we go live? Please click here.

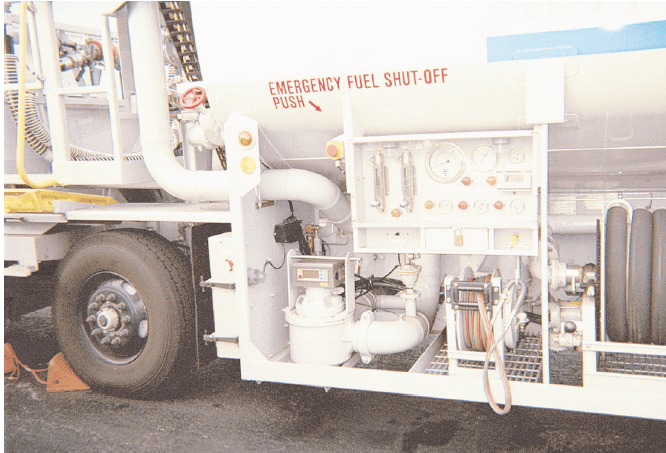

Fuel Bowser Automation

EMR3 ELECTRONIC METER REGISTER – The Next Standard in Electronic Register Systems

The new generation of electronic meter-register, exemplified by Veeder-Root’s EMR3, wraps the latest technology within a robust/user-friendly system, providing unprecedented value for customers worldwide. For over four decades, Veeder-Root’s Mechanical Register has set the global standard in quality, performance and value. We carry on that tradition with the EMR3.

VMI Management

Smartflow has strong competencies in creating solutions in that guide and improve the management of Vendor Managed Inventory, particularly in the fuelling area.

Using an admixture of processes, workflows, Automatic Tank Gauge, and our Fuel/Fluid Management Systems, Smartflow develops and deploys a solution that benefits both supplier and user.

Are you a VMI supplier or User? Talk to us today.