Automatic Tank Gauges – ATG Control Panels

The most frequent level instrumentation task is level control and limit level switching whether if the measurement medium is liquid or solid. This is the reason why SMARTFLOW focuses on level switches in addition to the level transmitters.

SMARTFLOW supplies the instruments that offer reliable level control and limit level switching solutions for most media from potable water to sewage, aggressive alkalis and acids, or free- flowing, powdered, bulk or granular solids. Thanks to this very wide level switch selection we are able to provide suitable instruments for most level instrumentation applications.

Most of our level switches have explosion-proof versions (in accordance to ATEX and/or IEC Ex). Moreover we offer suitable solutions for special requirements, for example the ship-building industry with a need for Germanischer Lloyd (GL), Det Norske Veritas (DNV), Bureau Veritas (BV) or SIL approvals.

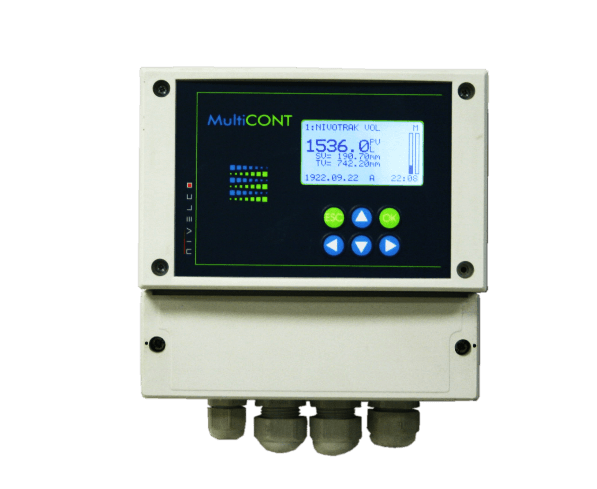

- Compact, efficiently designed. 7”full-colour-touch-screen display

- Simple for authorised users to understand and operate while eliminating unauthorised access.

- Easily manage multiple tanks. Supports up to 64 inputs (probes)

- Web-Enabled: monitor and control your automatic tank gauge system from any web browser.

- Able to store measurement values and three additional parameters of the connected transmitters in a measurement system into the internal FLASH memory or an SD memory card.

SYSTEM HIGHLIGHTS:

- Battery backed systems available

- No IT infrastructure required

- Can connect to Local LAN or GPRS network

- Flexible probes available for tall tanks

- 1000+ working probes around Nigeria

- DC versions available

Fuel Management Consoles

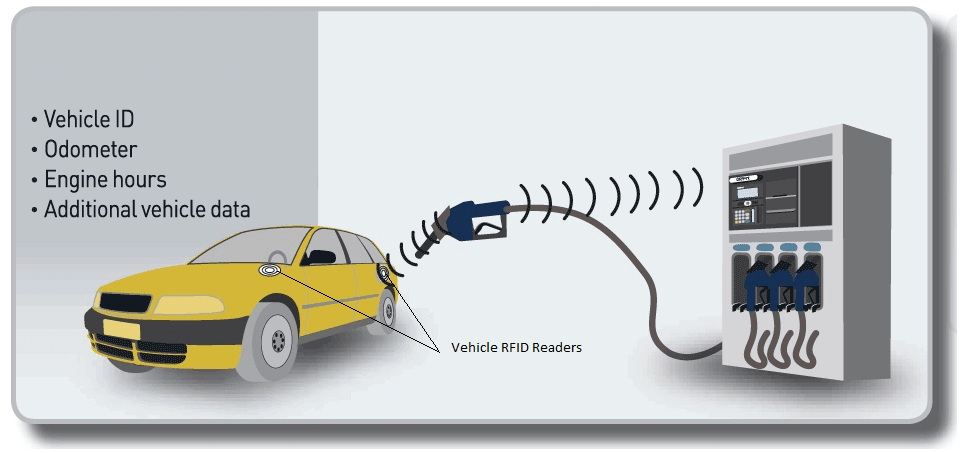

The fuel management console is destinated to car fleet managers wishing to supervise and to securize fuel supply.

Features

- Real time communication between terminals and servers, via internet or intranet.

- Quick and efficient thanks to search engine and reports generator that enable a flexible and real customization of the product.

- Longevity of the equipment thanks to the use of resistant materials.

- Scalability based on functional modules able to control the following devices: fuel dispensing, oil dispensing, gate opening, carwash, electrical vehicles charging…

- Real-time or stand-alone operating

- Multi-site

- Connection TCP/IP network – Modem – RS232/485 – Wireless

- Simultaneous management of 1 to 16 pumps for each terminal

- Identification of drivers and/or vehicles by code or by different kinds of badges (proximity cards/keyfobs, magnetic cards, etc.)

- Manages a maximum of 15000 drivers and 15000 vehicles

- Stores up to 2500 transactions

- Remote control and supervision

- Alarm trigger with e-mail, fax or sms notification

- Oil co. data input is performed easily. (Total, Shell, Esso, As24)

- Data output towards any application

- Real time transactions printing or tickets edition (optional)

- Automatic vehicles identity recognition (optional)

- Automatic mileage input can be performed directly from vehicles (optional)

- Digital tachograph driver card reader (optional)

- Simple web interface, accessible from any computer on the network.

- Management of fuel stocks, with levels’ chart

- Management of different kinds of users (passengers, subcontractors, customers, etc.)

- Management of maintenance actions with automatic recall

- Management of anomalies with recording of maintenance history, stocks states, variations in fuel consumptions, electrical shut down, etc.

Forecourt Controllers

Orpak’s Forecourt Interface Unit is a powerful device providing a single point of control for multiple forecourt devices – dispensers, ATG, price poles and payment terminals – from an impressive array of vendors. Its unrivalled flexibility reduces deployment, implementation and maintenance costs while providing better visibility into all equipment.

The Forecourt Interface Unit supports the typical forecourt data communication interfaces: LAN, RS-485, RS-232, proprietary dispenser interfaces and non-electronic device interfaces such as mechanical pumps. All interfaced devices are programmed via Orpak’s SiteOmat station automation software.

Like other Orpak forecourt devices, the unit is designed to withstand the extreme temperatures and harsh environment of retail fuel stations. It eliminates ground loops, power surges and RFI/EMI to maximize the performance and reliability of the station.

Features

- Fully integrated with over 60 types of electronic and mechanical dispensers

- Interfaces with any TLG

- Integrates with Orpak OrPT, OrTR, OrPAY EMV and third-party payment terminals

- Works with a wide variety of BNAs and price poles

- Easy installation and setup, including remote access capabilities

OrTR Tag Reader

The Orpak Tag Reader (OrTR) is a versatile pay-at-the-pump payment terminal for retail and homebase station fuel purchases, local accounts and loyalty schemes. Connecting to the station controller, it is a compact and cost-effective contactless card reader for magnetic swipe and MIFARE® fuel cards. The reader includes a large LCD, two LED status indicators and an internal buzzer that provides audible feedback.

Level Transmitters

Level Gauges & Transmitters

Since its foundation Smartflow has focused on the supply of industrial level measurement products. Our focus has not changed, demonstrated by our wide level transmitter portfolio employing many different types of level measurement methods. Our Microwave, Magneto resistive and ultrasonic level transmitter selection is definitely the widest on the market offering integrated, compact, 2- or 4-wire transmitters for liquids or solids with remarkable number of optional choices with precision upto ±0.1 mm of tank height

Float and Tape Type Tank Level Gauges

Float and tape tank gauges are suitable for almost all liquid storage applications and tank types. This Liquid Level Indicator have been the primary liquid level measurement products used by the petroleum market for over 80 years due to their simplicity and cost.

No Contact Type MICROWAVE Radar Level Gauges

-

- 25 GHz (K-band) measuring signal

- 2-wire compact transmitter

- Accuracy up to ±1 mm

- Measuring range up to 30 m

- Max. 25 bar and 180°C

- 4-20 mA + HART communication

- IP67 protection

- Explosion-proof models

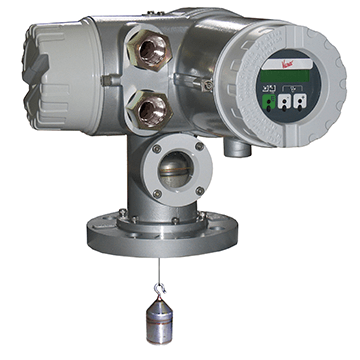

Servo Tank Gauges: Servo Tank Gauge (STG) product line provides an intelligent system for high accuracy liquid level measurement. It also determines the interfaces between three liquids, specific gravity of these liquids and tank bottom. To enable accurate volume calculation, a temperature device is integrated using HART® protocol or a 3-wire spot temperature connection.

High Accuracy – The STG is able to measure level to an outstanding accuracy of +/- 0.7 mm.

Density measurement – The STG is also able to measure two interface levels, spot density and perform density profiling throughout the liquid

GUIDED MICROWAVE Radar Gauge:

- 2-wire compact transmitter

- TDR principle

- ±5 mm or ±20 mm accuracy

- Measuring range up to 24 m

- 4-20 mA + HART communication

- Max. 40 bar and +200°C

- Rod or cable probes

- Plug-in graphic display module

- Explosion-proof models

MAGNETOSTRICTIVE TRANSMITTERS:

- 2-wire compact and mini compact transmitter

- 0.1 mm or 1 mm resolution

- Max. 15 m measurement range

- For liquids with min. 0.4 kg/dm3 density

- Distance, level and volume measurement and water level At Tank bottom

- Rigid or flexible probes

- OIML R-85 international certification

- Explosion-proof models

ULTRASONIC INTEGRATED:

- For liquid level measurement

- 2-wire integrated transmitter

- Narrow 5° beam angle

- Max. 25 m measurement range

- PP, PVDF, PTFE transducers

- 32-point linearization

- 4-20 mA + HART communication

- Open channel flow metering

- Explosion-proof models, IP68

Level Switches

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

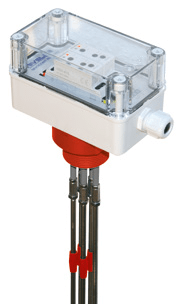

Float Switches

- Hermetically moulded, double chamber

- Adjustable switch differential

- Max. 20 m cable length

- Max. +50°C medium temperature

- Max. 2 bar process pressure

- Level switch from potable water to sewage

- Low specific weight of the floating body

- Fail-safe indication and pump control

- Suitable also for tanks and basins

- Low cost level switch

- Limit switch or differential switch versions

- Adjustable sensitivity

- Adjustable time delay

- All wetted parts stainless steel

- Compact and remote mount types

- For liquids with min. 10 μS/cm conductivity

- Rod probes up to 3 m

- Operation without power supply

- Micro-switch separated from the process

- All wetted parts stainless steel

- Fixed or adjustable switch differential

- Submersible versions

- For liquids with min. 0.7 kg/dm3 density

- Explosion-proof models

- Marine approvals, SIL approval

- Operation without power supply

- Reed switches separated from process

- Stainless steel probe and float

- PFA coated probe version with plastic float

- Up to 5 switch points

- For liquids with min. 0.4 kg/dm3 density

- Multi-point level switch in closed tanks

- Explosion-proof models

- For most liquids with min. 0.7 kg/dm3 density and max. 104 mm2/s viscosity & powdered solids with min. 0.01 kg/dm3 density

- No moving parts

- Self-cleaning for most mediums

- Stainless steel and plastic coated forks

- Rigid rod extension up to 3 m

- Explosion-proof models

- IP67, IP68 protection

Automatic Tank Gauges – ATG Control Panels

NIPRESS pressure transmitters working in 2- or 3-wire systems convert pressure (input signal) to direct current or voltage (output signal) proportional with the pressure. The wide choice of models provides possibility to complete almost all relative or absolute pressure measurement tasks requiring different accuracy. Their design, high overload capability and the possibility to install the units in any physical position allows for a wide range of industrial applications.

FEATURES:

- Compact Size

- Pressure ranges 0.6 to 400 bar

- Gauge or absolute pressure versions

- Fast output response

- Stainless steel housing

- High accuracy: 0.25% or 0.5%

- Standard plug type connector

APPLICATION:

- Measuring of gasses, vapours and liquids

- Overpressures and level measuring tasks

- Pressure switching

- Mounted on tanks, pipes or pressurised vessels

Flow Meters

Smartflow has bouquets of solutions that automate the flow processes for facilities that deal with flowing fluids. Complementing this solution we offer wide range of flow meters for different types of products and application requirements.

Fil-Rite Nutating disc Mechanical and Electronic Flow Meters

- Size – 1 & 1.5 Inches

- Application – Diesel , PETROL and Biodiesel

- 3 & 4 Digit Counter

- Non Resettable Totalizer

Oval Gear Positive Displacement Flow Meter

Meters provide exceptionally accurate service when using positive displacement metering principle, even under variable operating conditions (changes in temperature, pressure and viscosity). Provides the energy efficient and functional performance desired from an economical volumetric measuring instrument. Available with traditional mechanical seal or glandless magnetic driven pulse output device. A wide range of accessories are available to meet almost every metering need.

METER FEATURES

- a. High accuracy and repeatability

- b. Low maintenance, no metal-to-metal contact in measuring chamber

- c. Low pressure loss, a true gravity flow meter

- d. Choice of aluminum, cast iron, and stainless steel materials of construction

- e. Self-contained operation without electrical power or signal conditioning (for units equipped with mechanical registers, printers or pre-sets); no special piping requirements

- f. Electronic output and registration equipment where enhanced accuracy and electronic communications are needed

- g. Weights & Measures approval (world-wide) for custody transfer with mechanical or electronic registration systems meeting API standards

- h. Electronic accessories designed and approved to Class 1 Div. 2 standards

- i. Sizes: 1 1/2″ through 6″

- j. Flow Rates: 5 GPM through 1,000 GPM

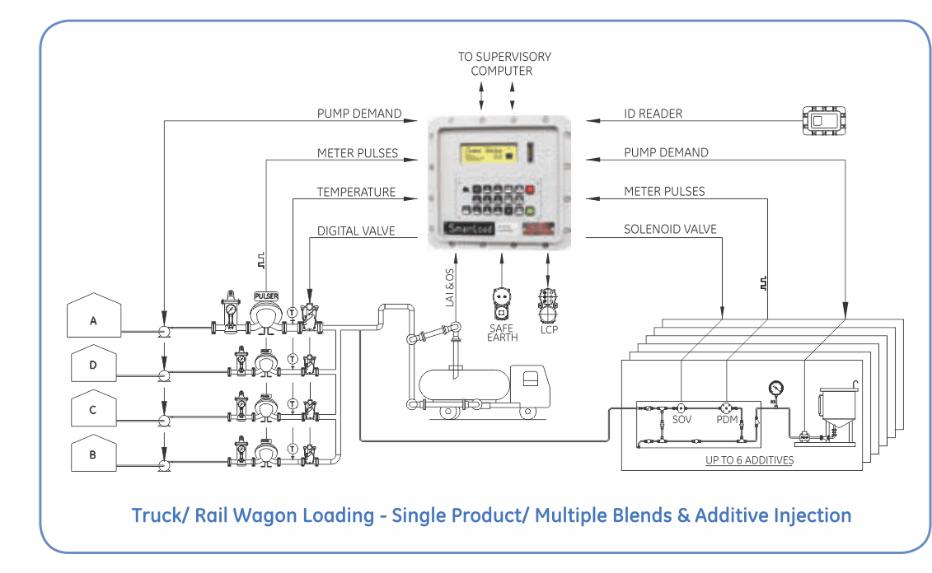

Batch Controllers

Batch controllers are used for liquid product distribution at truck, rail, marine, aviation and

pipeline loading and unloading facility. It precisely delivers preset quantity of product blends from tank storage or pipeline into vehicle, rail wagons, aviation or vessels.

Safety and Security

- Supports storage up to 500 proximity cards / touch keys that will be validated during manual mode of operation

- Possible to seal weights & measures switch to restrict the change of meter factors/ k-factor

- Audit logs for change in weights & measures parameters, if weights & measures switch is not locked

- Three levels of passwords: L1 – Super User (Can change all the parameters except W&M parameters if locked) L2 – Intermediate (Can only view all parameters ) L3 – Operator (Only acknowledge the alarms )

Salient Features:

- Incorporates modern technology in a cost-effective, self-contained enclosure providing accuracy and reliability

- Suitable for petroleum, petrochemicals, LNG / LPG, asphalt and specialty chemical applications

- Capable of loading Net LPG quantity deducting vapour quantity.

- Controls loading of base or blended product (up to 4 components) with or without additives & dyes (up to 6 additives). Blending can be configured for sequential, in-line proportional or non-proportional mode along with additive injection using various (up to 10) recipes

- User configurable transaction and batch archiving of selected parameters for storage and ticket printing (up to 2000 transactions).

- Configurable data logging / printing options for batch and transaction summery, alarm, meter proving, program mode change, power failure, weights & measures switch status etc.

- User configurable alarm text and alarm actions

- Optional secondary keypad and LCD display available for additional two-side loading or remote control application

- Temperature / Pressure compensation per API IP or linear methods

- Operates as a standalone unit or integrated with any Terminal Automation System

- User-friendly menu driven configuration facility

- Low installation and wiring cost

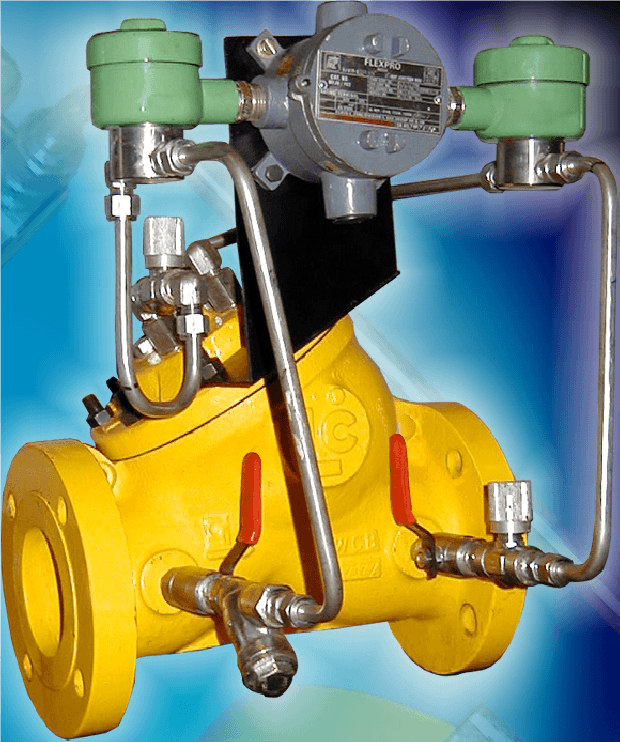

Digital Control Valves

The Digital Control Valve consists of a valve tubed with two solenoid valves. The solenoids are configured in normally open & normally closed position. These solenoids are connected to electronic batch controller. The batch controller provides signal to carry out two functions. Multistage opening & closing function to get smooth flow control, and precise batch quantities during loading operation of loading racks, Bulk Plants or processing installations.

The Digital Control Valve are hydraulic, diaphragm actuated control valves. The “Y” type globe body is a hydro dynamically balanced design for high flow rates, minimum head loss and maximum cavitation resistance. The valve body includes a full bore removable seat provided with a bottom guide rib for maximum assurance of complete valve shutoff. The entire actuator assembly may be removed as a unit using only simple common hand tools. The diaphragm actuator and trim provide smooth, accurate and controlled operation assuring bubble tight shut offs.

Features

- “Fail safe” to close design

- Easy maintenance with on line servicing

- Bubble tight shutoff as per ANSI B16.104

- Low pressure loss

- High C value size 80 mm =148, size 100 mm = 204 v

- Horizontal/vertical installation

- All critical parts are imported

- All trim, tubing, fittings and accessories are Stainless Steel for superior service.

- Compact, robust design

- Thermal relief downstream to upstream standard and upstream to downstream optional

- Opening and closing speed control with position locking

- 40 mesh strainer, externally removable for cleaning, a standard feature

- Explosion proof junction box with standard terminal block

- Optional manual override feature

- Ideal for loading rack and bulk metering applications.

- Optional Limit Switch for Position indication.

Strainer & Air Eliminators

Smartflow offers basket type strainers for variety of installations and conditions and designed for straining and filtering of wide variety of fluids.

As unfiltered liquid enters the strainer, will directly pass through basket in which almost all impurities are trapped into the basket and only clean liquid will pass through to the outlet of the strainer. Advanced dynamic flow and large filtration area elements ensure low pressure drops and reduce maintenance period. Also, it is prevented by “O” Ring seal between basket flange and strainer internal flange, as well as retain position of basket even in case of reverse flow.

Basket strainers are normally installed before the measuring devices like Positive displacement meter or turbine meter which increases accuracy of the measuring devices.

We offer basket type strainers from 11/2” to 16”size with flow range up to 800m3/hr for pressure range up to 200 bar & design as per ASME Section VIII div I latest edition. We also offer duplex and jacketed type strainers.

Air Eliminators

Smartflow also offers Bulk Plant Air Eliminators for variety of installations and conditions and designed for separation, elimination of air from main product.

Positive displacement meter of turbine meter, is a volumetric measuring device, cannot differentiate between liquid, air and vapour. So when liquid enters with air or vapour into this measuring devices, it will contribute the measurable error. Large amount of free air or vapour entrapped in the piping system, not only compromising meter accuracy but also lead to over speeding of meter and creating excessive wear or unit failure to ensure accurate liquid.

Measurement is necessary to remove all air from the system before entering into the measuring devices. Hence bulk plant air eliminator is installed before the meter for accuracy of the measurement devices.

Air Inflators and Nozzles

Freestanding Tyre Inflator with Compressor

Specifically designed for sites where a compressed air supply is not available. The stylish stainless steel FSC is supplied standard with a twin head compressor built into the enclosure. The FSC is ideal for locations where customers need to regularly check or adjust their tyre pressures, such as council parking bays, hire yards, fleet vehicles depots, bicycle storage bays and enclosures, hire car service bays and service station forecourts. The default and maximum pressure can be pre-set.

Product Features

- In-built high pressure, long service life compressor

- Stylish stainless steel enclosure suits any forecourt or parking bay area

- Corrosion free, vandal resistant and designed for easy maintenance

- Stainless steel buttons for long service life (optional Piezo buttons)

- Standard 10 metre black air hose with fittings

- Large easy to read backlit LCD display

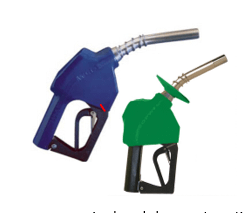

Nozzles

The OPW 11® Series automatic nozzles are OPW’s premium conventional nozzles for safe retail and commercial petroleum filling. The OPW 11® Series is the most trusted conventional nozzle in the world for full service use. The OPW 11B® series is designed for use in retail and commercial filling applications including pre-pay, self and full-service, credit/debit card readers or card-lock systems to help prevent gasoline spills. The OPW 11B® will not open until the pumping system is pressurised, and closes automatically when the pressure is removed.

Features & Benefits

Safe for Use

- Prevents gasoline spills in prepay or card-lock systems utilising OPW’s unique No Pressure – No Flow Device. The nozzle cannot be opened until the pumping system is pressurized and closes automatically when the pressure is removed.

- Prevents customer from jamming the nozzle in an open position – Blocker on lever guard. FlowLock™ allows nozzle to shut-off when falling out of a vehicle, and tipped up limiting spillage and unsafe conditions.

Durable & Long –Lasting Design

- Cycle-tested and proven to last longer than 1 million cycles – Better than any other nozzle available on the market today.

- Durable lever guard that won’t scratch your customers’ vehicles

Appealing to Customers

- Easy to use

- Attractive 2-piece Newgard™ Hand Insulator is the most comfortable nozzle in the industry to use.

- Convenient – One fingerhold-open clip that is easy to set the flowrate.